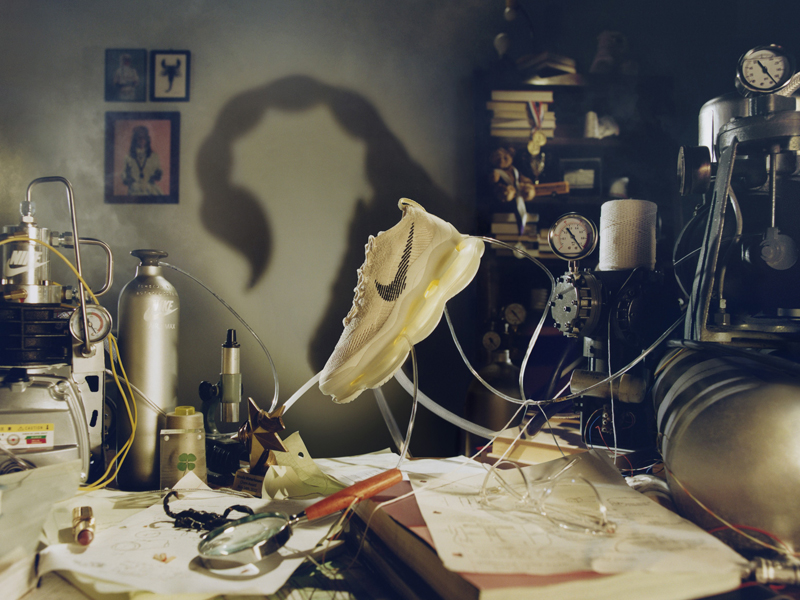

A New Age of Air: the Air Max Scorpion

Can’t. Look. Away.

While there have been unique and out-of-this-world designs come our way, this fits right into the last few years we’ve been in. This is the new age of Air – the Air Max Scorpion.

On the average, a shoe is usually developed over 24 months (2 years), depending on how the technology is folded into the design and how new innovations change the overall direction for the brand. With the world essentially stopping during the pandemic, Nike’s design team had 18 months to create the Air Max Scorpion. Taking a radical system of Air units, transforming simple forms into complex new geometries, making for a unique sensation underfoot.

The design team used a new VR design software and simulation tools to create the shoe. The team used data gatherd from the NSRL, and tested/prototyped thoe shoe through both Finite Element Analysis (FEA) and in-house rapid testing of virtual prototypes, reducing the need for actual samples to be made.

Nancy Eisenmenger, Expert Materials Researcher, noted that this improved the overall process to find the edge of the material’s limits and optimize its performance and manufacturability without any aesthetic compromise. Before, it took roughly 8 weeks to test a single idea, now things can be done at a dozen at a time in a span of just five weeks. Computational design helped identify the optimal outsole traction pattern and grade the shoe’s performance benefits across sizes, with Air MI (Manufacturing Innovation) developing over 14 different tooling sets.

The result of all those is the most Air in terms of pounder per square inch, fine tuned across sizes. The Air Max Scorpion’s airbag system provides a piston-like effect, strategically determined, point-loaded contact points between the foot and airbag. The shoe’s upper is made of a Flyknit chenille upper, making for a new creation altogether.

The Air Max Scorpion, which is twenty-percent recycled content by weight, launches October 5. Stay tuned on our platforms for its local release.